- Shenzhen Zhilian precision machine Technology Co., LTD

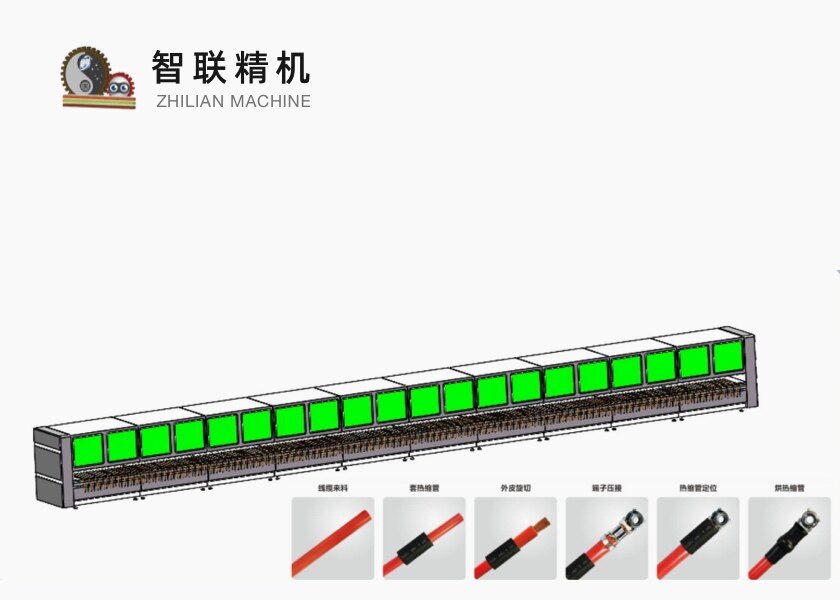

- Main products: FAKRA Harness Automation Equipment, HSD Wire Harness Automation Equipment, Ethernet Harness Automation Equipment, New energy harness automatic production line, Cable automation equipment, Wire harness post-processing equipment, Ethernet harness automation equipment, New energy high voltage line automation equipment, Double head coaxial stripping machine, Color sorting device, Double-sided soldering equipment, Double-sided glue spraying equipment

Home > Company News > New energy high voltage line automation equipment

-

Mr. Liang

Welcome to my shop, I'm glad to serve you. Please feel free to send me any questions you may have.

Mr. Liang

Welcome to my shop, I'm glad to serve you. Please feel free to send me any questions you may have.

Your message has exceeded the limit.

Company News

A few days ago, a customer of our company came to complain that the pipe cut out by the automatic pipe cutting machine bought before is uneven, slightly deformed, and has raw edges, and asked me how to solve this problem. At that time, I was a little confused, because these problems are process problems, either from the existing automatic pipe cutting machine to find the problem, or purchase polishing equipment for secondary processing. Of course, the way is to replace a better pipe cutting machine.

If you are looking for problems from your existing automatic pipe cutting machine, you may wish to check whether the fixture is not tight or too tight, because these two situations may lead to deformation or burr problems in the pipe. In addition, you also need to check whether the saw blade is sharp, or buy a better saw blade to cut. If the above two cases are excluded, then it is likely that the equipment itself is not enough power or the cutting speed is not fast and other mechanical problems lead to the phenomenon of uneven or rough edge at the pipe mouth, for this situation, only a better pipe cutting machine can be considered.

If the second scheme is considered, that is, the purchase of polishing tools for secondary processing can solve problems such as raw edges. However, this will lead to the increase of the company's production process, slow down the production speed, increase the production cost, the gain is not worth the loss. If the requirements for the nozzle are not very high, it is recommended not to use this method as far as possible.

If you want to consider replacing a better pipe cutting machine, and hope to achieve no deformation and no rough edge in one processing, you may wish to learn about the newly developed intelligent pipe cutting machine, compared with the current automatic pipe cutting machine on the market, the pipe cutting machine has five advantages: 1, automatic feeding automatic feeding, 1 person to operate more than no problem, saving labor and production costs; Second, cutting pipe mouth comparable to laser cutting, no burrs without deformation; 3, can automatically identify the head and tail and cut, can cut different specifications of pipes at one time, almost zero tail material; Fourth, the accuracy is more, can reach the national standard tolerance range, and the quality of the pipe mouth is good; Fifth, the price is reasonable, it is slightly more expensive than the automatic pipe cutting machine on the market at present, but the new process is simpler, more and more cost saving for customers!